The confusion around different centers on a lathe is not exclusive to newcomers. The difference between live vs. dead center has always been less than a cut and dry. It is understandable because naming conventions in the woodturning community are not entirely standardized, leading to one thing being called multiple names by different people.

The simplest explanation is the difference between live vs. dead center on a wood lathe is that a live center has moving parts and a dead center does not. A live center has ball bearings that allow it to turn, and the dead center is a hardened piece of metal with a point. Each type comes in a variety of styles for different needs.

While the differences between the two can be boiled down to one move and one does not, the specific applications of each are far more involved. If you’re interested in the difference between live vs. dead center, this article is for you. Keep reading for more on the difference between live vs. dead center on a wood lathe

Live Center vs. Dead Center on a Wood Lathe

To fully understand what each of these types of centers is used for, we need to understand the basic anatomy of a lathe and some of the technical words used around it and woodturning. The lathe has two ends on it, the headstock and the tailstock.

The headstock is the end where the motor is or where the lathe will get its power from. The tailstock is the other end that can be adjusted along the lathe’s bed to accommodate different sizes of wood.

Centers are pieces of metal with points at the end that go on either the headstock or tailstock to hold the wood in place when turning.

Explaining Live Centers

Live centers are centers that can rotate freely. Initially, when woodturning on a lathe was in its early day, dead centers would be used on the headstock and the tailstock.

However, as technology advanced, the dead center on the headstock was replaced by a live center, and eventually, live centers became the standard for most people in most applications. The reason for this is that having a dead center in your tailstock produces a lot of friction and can cause burning on the wood. Live centers, on the other hand, can move freely and allow for quicker turning speeds without the need for lubrication.

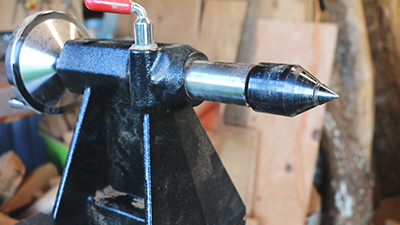

Live centers have a tapered shaft called a Morse taper that is inserted into either the headstock or tailstock, and the point has a ball bearing that allows it to move. It is excellent for providing extra support when doing spindle work, especially for work that’s done between both centers, because you can clamp down on the wood hard and not have to worry about friction.

Live centers will sometimes also have different points that can be switched out. Because it does not have to be a solid piece of metal like the dead center, it is easy to have a hollow area in the center that you can put a knock out tool through to knock out your point and replace it with a different one.

This makes live centers versatile and is one of the reasons they are so popular today.

Variations of the Live Center

Live centers come in a few different varieties. We have covered the standard already, spring-loaded centers, pipe centers, and cup centers.

Spring-loaded centers are live centers that have a spring inside that allows you to get consistent tension on the point that is designed to compensate for the difference in centers. Pipe centers, also known as bullnose centers, are live centers with a cone-shaped point with a broader diameter instead of the sharp point of the standard live center.

Cup centers are like standard live centers except that they have a ring surrounding the point. This ring is designed to provide additional support to the wood and keep it from splitting when under pressure.

How Does the Wood Turn?

You may be wondering how the wood can turn if a live center is put on the headstock. If the motor is turning the bearings, wouldn’t the point stay still?

The reason live centers work is that the point turns and offers a certain amount of resistance. This resistance is another reason why live centers have grown in popularity.

It has allowed for resistance similar to what you get on a dry center, but if your tool catches on the wood, it is more likely to spin freely and reduce damage.

Explaining Dead Centers

Dead centers do not move. They are solid pieces of metal rod that have a point that goes into the wood you are turning. Dead centers can go on either the headstock or the tailstock but having it on the tailstock creates a lot of friction.

Typically, you only want to have a dead center on the tailstock if you will be spinning slowly. Additionally, you will need some lubricant. People use bearing grease, automotive ep grease, and supposedly back in the early days of woodturning, ear wax.

Naturally, dead centers are hardened solid bars with a point to maintain the angle of the point. However, there are also soft dead centers designed explicitly so that you can grind it into the angle you want.

While live centers are more popular now, dead centers do have their uses. When you are working with bigger and heavier pieces or when you need the wood to be rigid, dead centers are great.

Milling is an excellent example of this. They might also be used on pole lathes, which are often built to be correct to a specific time. Additionally, having a dead center on the headstock end will not cause as much friction because the solid metal will move with the wood. Dead centers will also have a Morse taper just like the live center.

Variations of the Dead Center

There are fewer variations for dead centers than there are for live centers. The two notable ones are the drive center and the half-dead center. The drive center is just like a regular dead center but has teeth around it to better grip.

This works exceptionally well with softwood because the teeth can get a grip, hence why it is also called a grip center. This type is only used on the headstock, though. The other type is the half-dead center.

This is exactly like a regular dead center except that a small portion of the tip is flattened. It will look as if the cone-shaped tip of your dead center had some of the roundness shaved away.

In reality, some people do exactly that to their dead centers to make their half-dead centers.

Other Types of Centers and Additional Factors

Dead centers and live centers are the two most common types of centers, but there are plenty more out there. Some of them will fall within the category of either live or dead center, but some are specialized and may not.

You can find things like the swivel v style center, the self-driving live center, the ball center, and many more. It is essential to keep in mind that naming conventions in a lot of woodturning have not been standardized yet. This means that when you are looking to buy your centers, make sure that you are getting the size and style you need.

You will need to keep in mind the material you are working with, the taper size of your lathe, the RPM of your lathe, and several other factors. Make sure to do your research to keep your tools and machine working correctly, and to keep yourself safe.